Testing Facilities

particles DIMENSIONS UP TO PICO METER

Particles Dimensions up to picometer through Micro Scope.

offering Rubber testing facilities for the first time in Pakistan

For the first time in Pakistan, Darson industries offer rubber testing facilities to other businesses. Our state of the art and PNAC accredited labs are capable enough to meet your testing needs.

Hardness Testing

Rubber hardness is checked by ASTM D2240:2015 by using digital durometer with mounted on stand which designed on JIS k 6253

Density Testing

Density of solid rubber specimen is checked by ASTM D297:15 by using electronic densimeter which is designed on

Compression Test

Permanent deformation of rubber at elevation tempearture is checked as per test menthod ASTM D395:2018

by using Heating oven and compression jig.

Rheology Test

Curing characteristics of rubber compound is determined in accordance with the ASTM D5289-17 and ASTM D2084-17 by using Rotorless Rheometer (MDR-A) and Rotorless Rheometer (MR-C3).

Mooney Viscosity Test

Mooney viscosity of rubber and rubber compound is determined in accordance with ASTM D1646-17 by utilizing Mooney Viscometer (MV-C3).

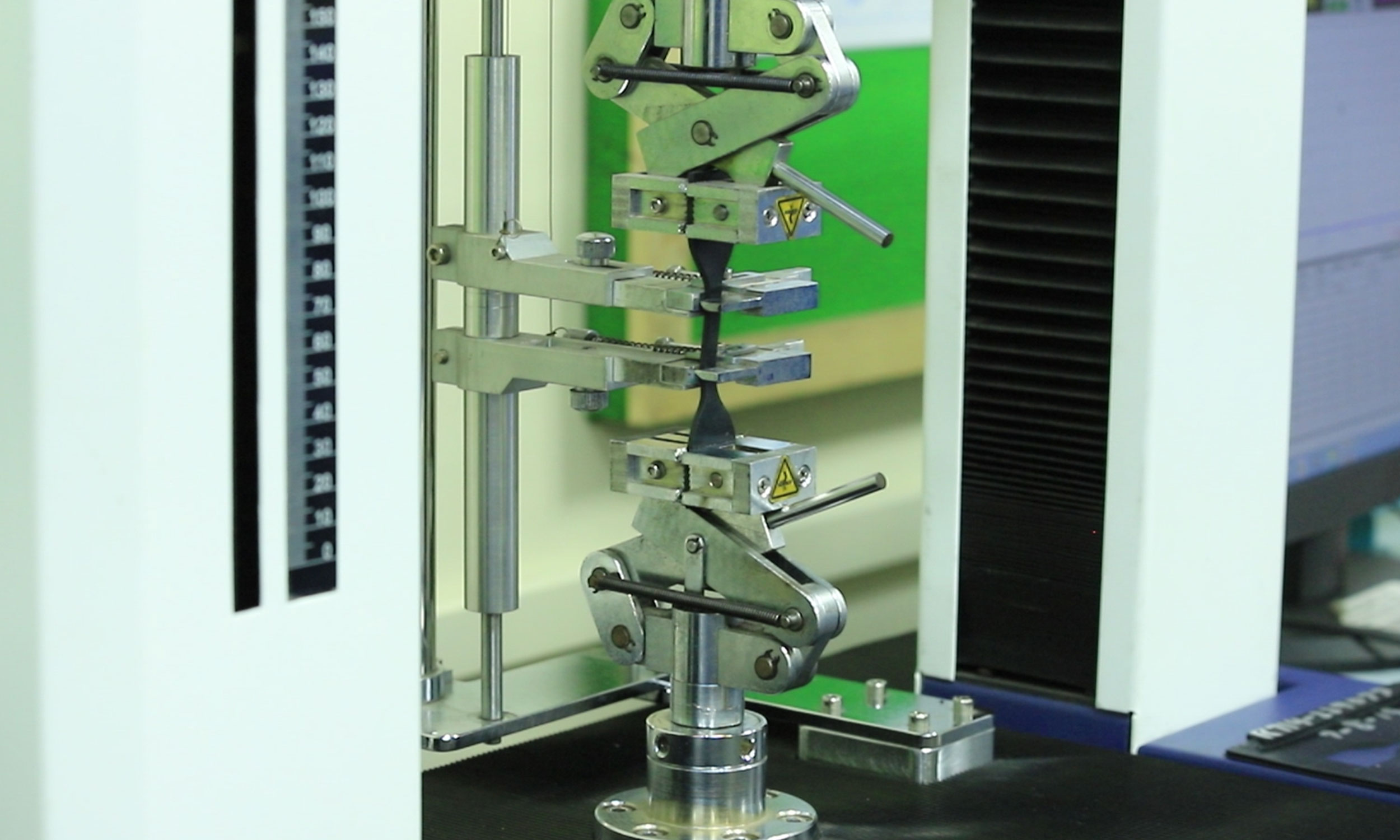

Tensile Test

Tensile Strength of cured rubber specimens is determined as per test method

ASTM D412-16 Universal Tensile Tester (RT5K-2)

Ultimate Elongation

Percent change in strain (Elongation) of cured rubber specimens is determined as per test method ASTM D412-16 by using Universal Testing Machine (RT5K-2).

Tear Strength

The force required to tear a cured specimen of rubber is determined in accordance with ASTM D624-00e1 by using Universal Tensile Tester

(RT5K-2).

Heat Aging

Resistance to aging of solid rubber specimen is checked by as per test method

ASTM D 573-04(2015) by utilizing heat aging oven.

Ozone Resistance

Resistance to ozone of solid rubber specimen is determined in accordance with

ASTM D1149-16 by using Ozone Chamber.

Fuel and Oil Resistance Test

Resistance to fuel and oil of cured rubber specimen is checked as per test method

ASTM D471-16a by using thermostat Oil Bath and thermostat Water Bath.

Carbon Black Dispersion Test

Dispersion of carbon black filler in rubber compound is determined in accordance with

ASTM D2663-14 by using Carbon Dispersion Analyzer.

Cold Flexibility Test

Resistance to cooling of cured rubber specimen is checked as per test method

ASTM D2137-10 by using Temperature & Humidity Chamber.

Surface Straining Test:

Straining of rubber compound specimen surfaces at low temperature is determined by contact surface by using Temperature & Humidity Chamber.

Burst Strength Test

Burst Strength of rubber product (Hoses) is determined as per test method

SAE J 20-03 and SAE J 30-12 by utilizing pressure tester machine.

Pressure Resistance Test

Resistance to pressure of rubber hose is measured as per test method

SAE J 20-03 and SAE J 30-12 by using pressure tester machine

Vacuum Test

Resistance to the negative pressure of rubber hose is determined in accordance with

SAE J 20-03 and SAE J 30-12 by utilizing a Hose vacuum tester machine.