Tool Making facilities

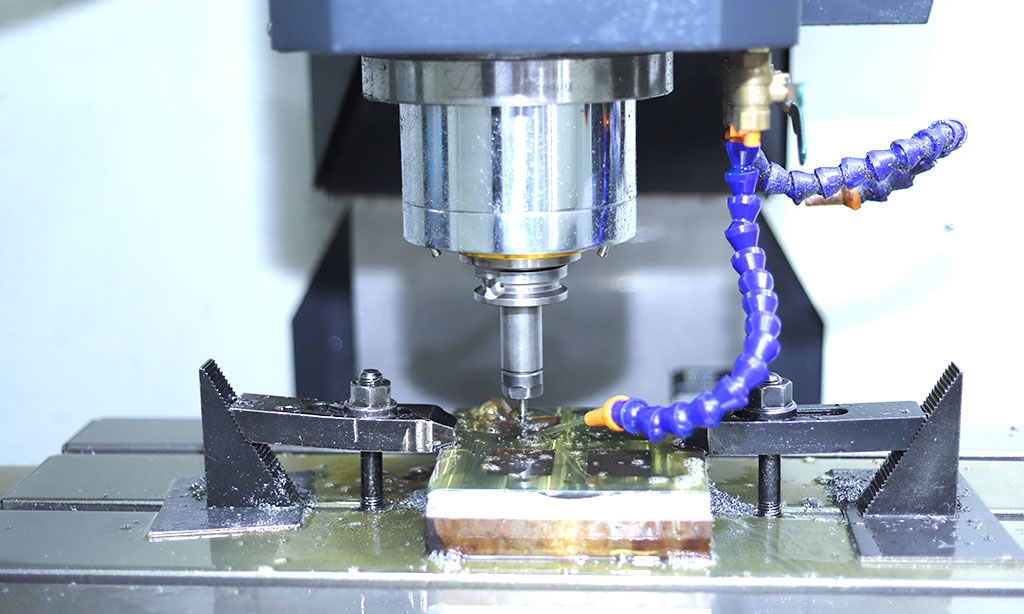

CNC tool machining

In this process, after designing and verification of tool with the simulation process. And then we start the following processes.

CNC Milling Process

CNC Turning Process

CNC EDM Wire Cut Process

CNC EDM Process

Benchwork Process

tool bench work process

In the benchwork, our skilled team members fabricate tools according to drawing very after completion of the tool machining process. this process is also used to develop support tools and accessories that are needed in routine production.

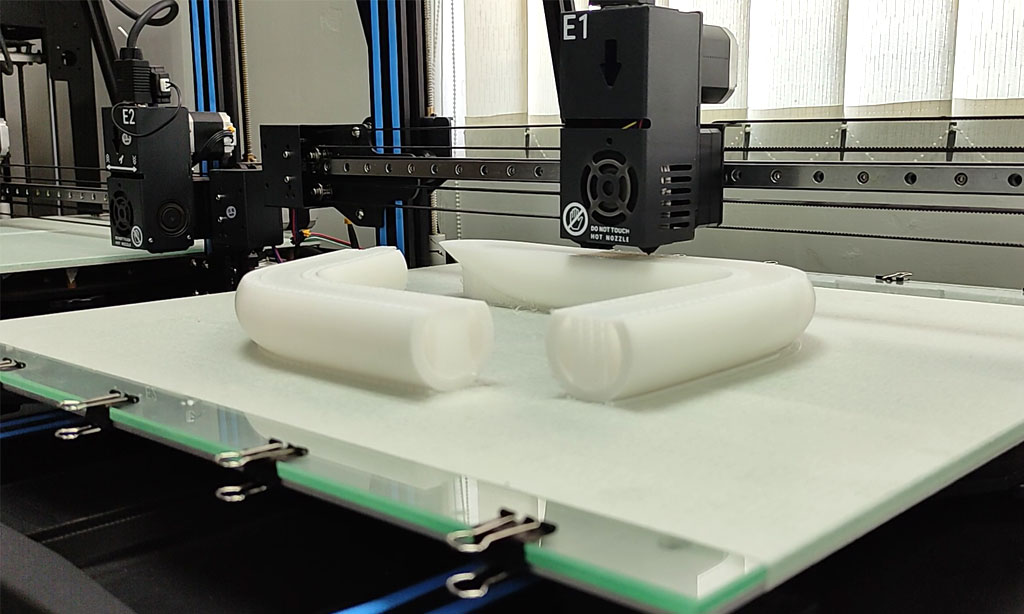

rapid prototyping

Darson now has an in-house RAPID PROTOTYPING facility through 3D printers that use either customer-provided CAD data or data converted to CAD format at the internal Engineering & Development department. The use of these 3D printers is not limited to develop inspection aids like jigs and fixtures with the best possible accuracy and precision.

conventional works

Where there is no technical information available for our valuable customer, Darson uses some conventional techniques to realize the product (organizational knowledge & reverse engineering). For example, using customer-provided sample tool(s) is(are) designed for Prototyping for customer approval followed by serial production. Such a process includes certain mechanical processes like milling, lathe operation, drilling, laser cutting/ engraving, grinding and welding, etc.

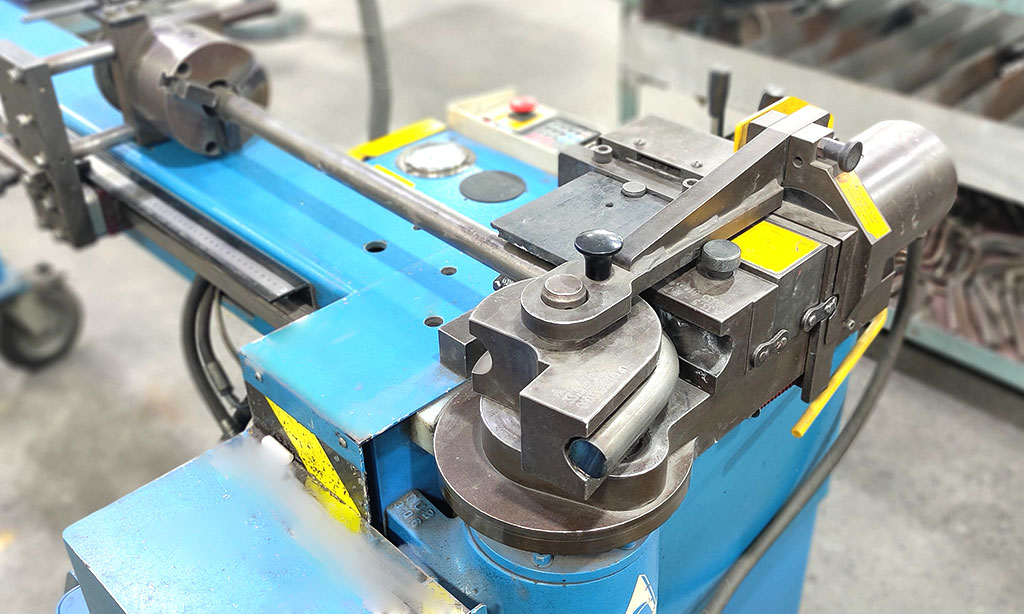

numeric control bender

We use NC Bender for tooling bending, especially for large quantities when we have details like coordinates with bending radius. This allows us to have tools with the least variation and to use mild steel and/or stainless-steel pipes for tooling instead of solid rods.

tools inspection

For tool inspection purposes we are using the following tools. For quality assurance. An Inspection Report is then generated accordingly.

Vernier Caliper

Radius Gage

Filler Gage

Pie Tape

Height Gage

Farrow Arm