Product Development

In-house mould, mandril and fixture making workshops

To ensure the proper Design & Development of Mould and Mandrel.

CNC and TWSP department are responsible to carry out all the activities of Mould and Mandrel development and co-ordinate with the concern departments to ensure the Mould and Mandrel development on time.

Material Arrangemet and Inspection

Machining with CNC Milling, Turning Center, Wire Cut

Mold Assembly, Polishing and Inspection

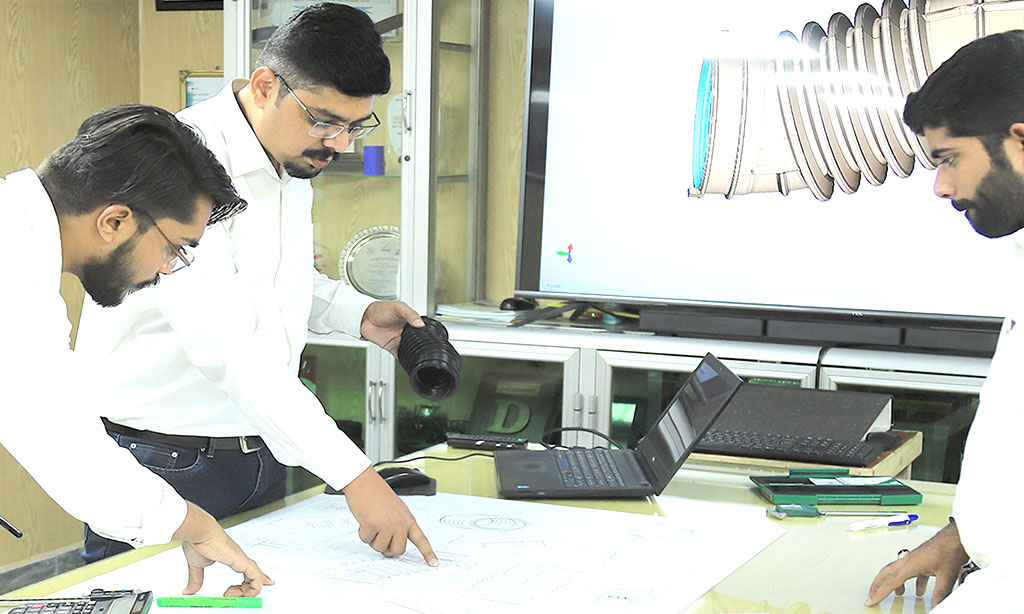

CROSS FUNCTIONAL FEASIBILITY & PROJECT REVIEW STUDIES

The Automotive Core Tools include Advanced Product Quality Planning (APQP), Failure Mode and Effects Analysis (FMEA), Measurement System Analysis (MSA), Production Part Approval Process (PPAP), Statistical Process Control (SPC) and (additionally) the 8D method. The Automotive Core Tools are therefore proven and required methods for quality planning and control. The use of these quality methods supports employees in securing and improving processes and procedures and forms the basis for an effective quality management system in accordance with the requirements of the automotive industry.

Automotive Core Tools

The Automotive Core Tools include Advanced Product Quality Planning (APQP), Failure Mode and Effects Analysis (FMEA), Measurement System Analysis (MSA), Production Part Approval Process (PPAP), Statistical Process Control (SPC) and (additionally) the 8D method. The Automotive Core Tools are therefore proven and required methods for quality planning and control. The use of these quality methods supports employees in securing and improving processes and procedures and forms the basis for an effective quality management system in accordance with the requirements of the automotive industry.

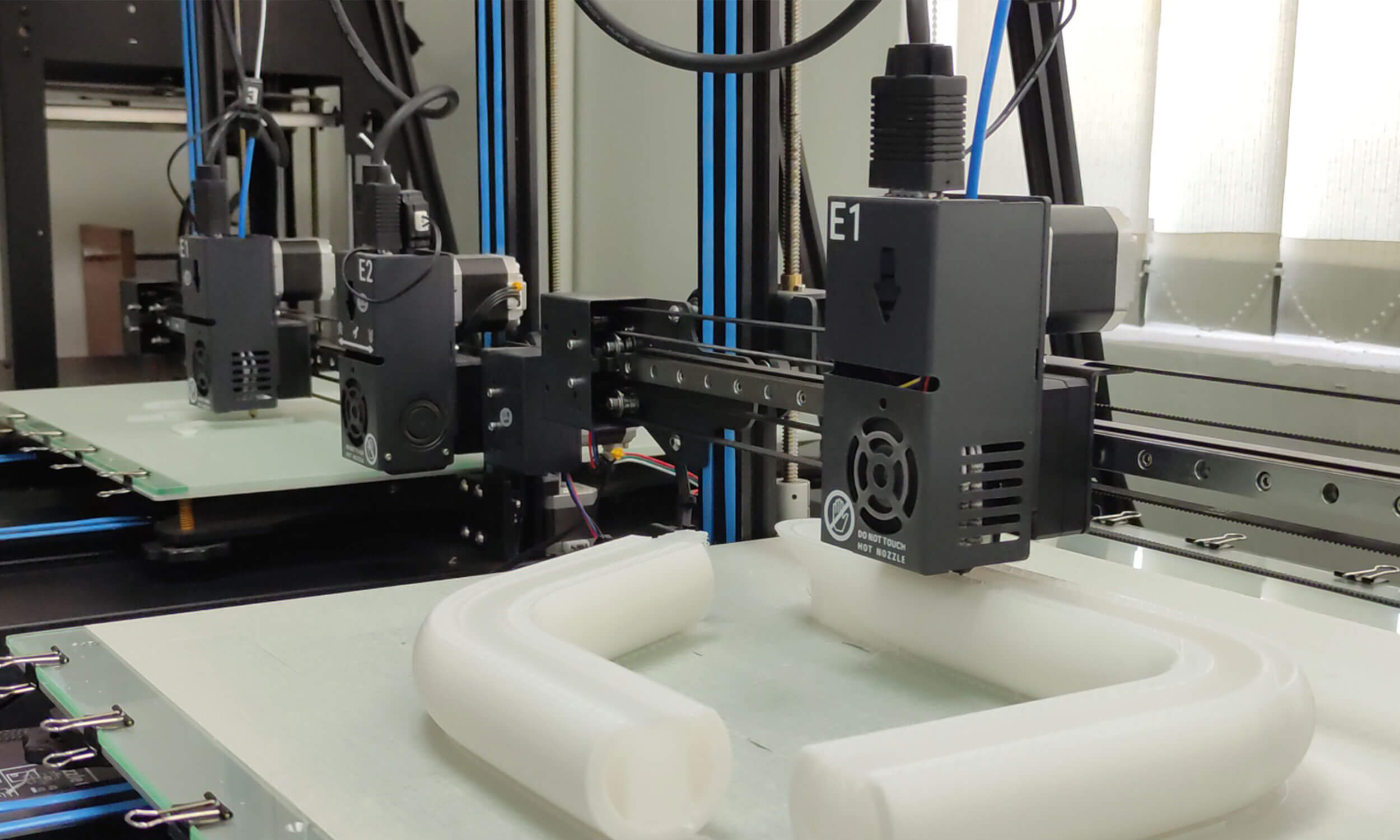

3D Printing for rapid prototyping

The Automotive Core Tools are therefore proven and required methods for quality planning and control. The use of these quality methods supports employees in securing and improving processes and procedures and forms the basis for an effective quality management system in accordance with the requirements of the automotive industry.

Measurement System Analysis

Measurement System Analysis (MSA) is an experimental and mathematical method of determining how much the variation within the measurement process contributes to overall process variability.

Measurement Systems Analysis allows us to make sure that the variation in our measurement is minimal compared to the variation in our process.

The purpose of MSA is to assess the error due to measurement systems.

The error can be partitioned into specific sources:

Precision

Repeatability – within an operator or piece of equipment

Reproducibility – operator to operator or attribute gage to attribute gage Read More